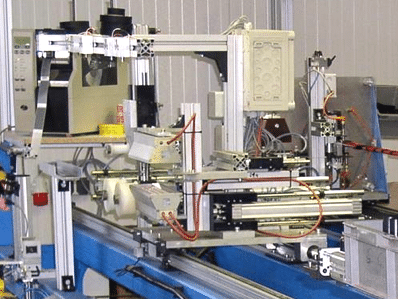

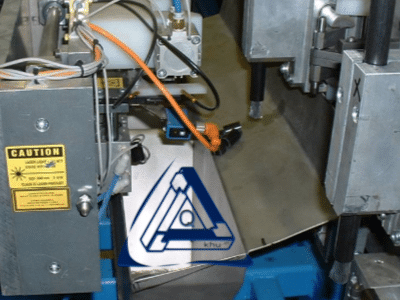

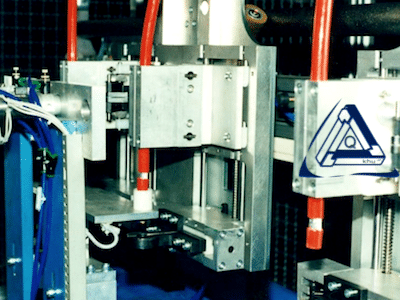

This construction is built for the automatic harnessing of cables (wires) and cable loops for the automotive industry. This KHU cable assembly plant handles two-componant glued and pressed cable shoes. It produces and insulates the cable loops and afterwards tests and monitors the finished product. The entire plant is operating automatically, ensuring high-end quality products for maximum safety of the end customer.

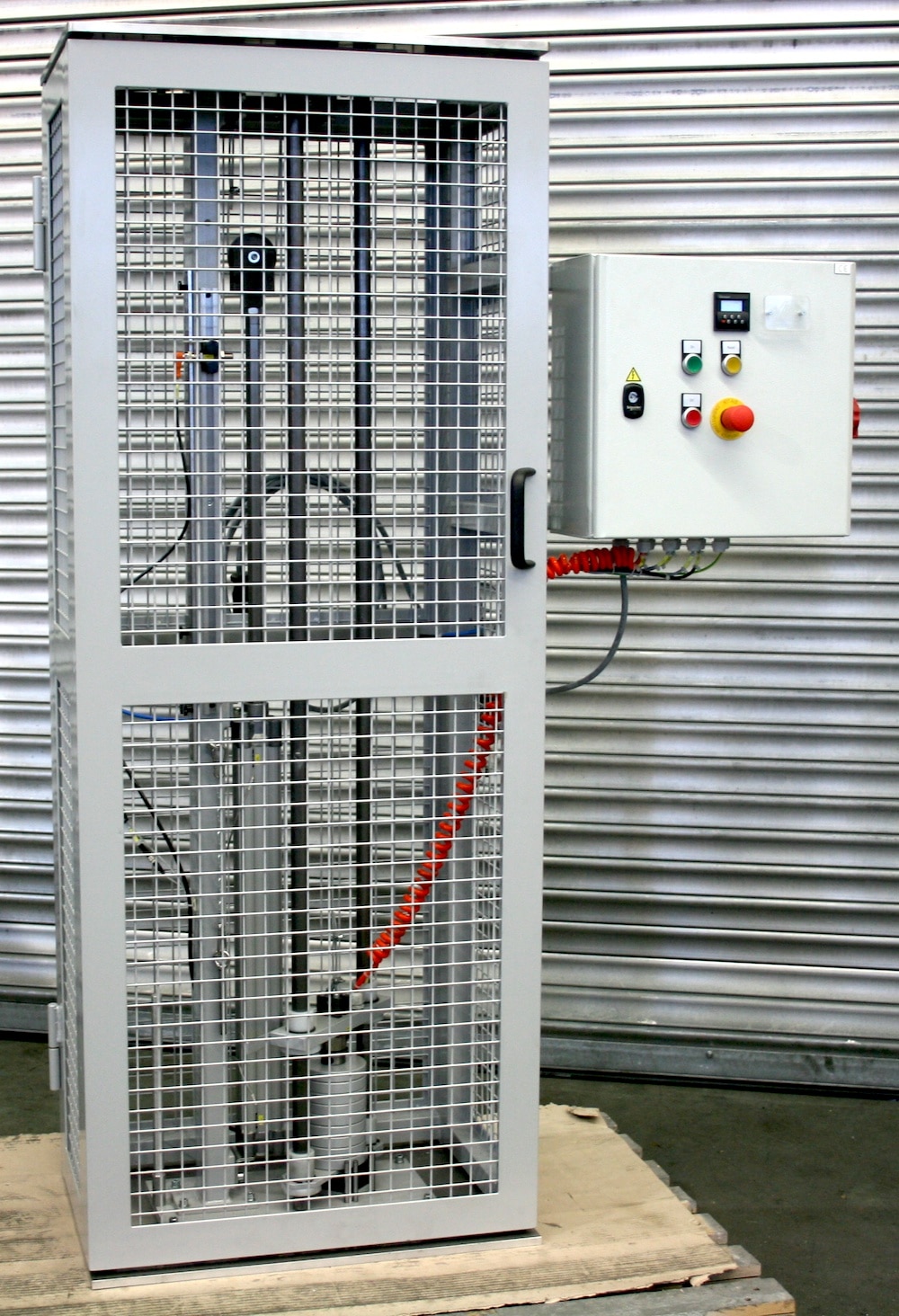

The belts can be individually adjusted according to your requirements. Pressing and tensioning can be done mechanically and pneumatically. The desired pressure can be steplessly adjusted. The high number of reels results in less wear and tear of the belts and a soft handling of the product (e.g. cable). According to your requirements the capstan could be equipped also with a three-phase motor and a gear box.

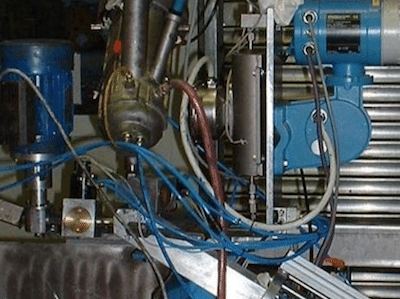

The cable sample is put into the testing device and clamped at the designed places.

The desired tensile force has to be defined.

An automatic STOP is possible after the expiry of the programmed time.

Pulling force pneumatic: 100 – 5.000 N

Testing length approx. 600 m

Pulling force hydraulic: 4.000 – 30.000 N

Testing length approx. 600 m

Pulling force hydraulic: 4.000 – 50.000 N

Testing length approx. 360 m

Cable diameter: 5 – 40 mm

According to IEC-794-E4

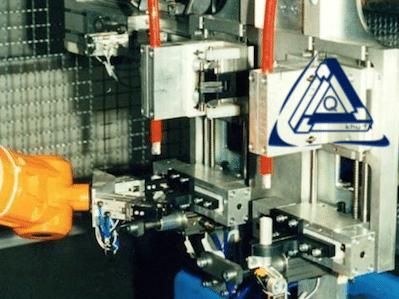

The cable sample is clamped between two clamping jaws.

A weight which is located on a guiding unit is adjusted and released automatically and moves in free fall downwards onto the cable sample.

An automatic STOP is possible after the expiry of the programmed time.

This test can be executed automatically and manually.

The required mounting equipment for two different cable diameters comes with the testing apparatus.

Cable sample diameter: 3 – 40 mm

Cycles adjustable: 0 – 30

Fall height adjustable: 500 -1.000 mm

Radius of hammer: 300 mm

Weights: 1 – 10 kg (10 x 1 kg)

according to IEC-794-1-E7

Technical Data

Cycles: 0 – 40

Tension stress of specimens: 1 – 10 kg

Clamping device intake: 5 – 40 mm

Length of testing cables: 100 – 2.000 mm

Central pass: max. 30mm

Clamping device for diameter 5mm and 35mm included

Clamping device for diameter (dimension at buyer`s option)

according to IEC-794-1-E6

Technical Data

Cable diameter: 3 – 40 mm

Bending radius: approx. 10 times wire diameter 50 / 350 mm include

Cycle: 0 – 30 strokes

Tension weights: 1 – 10 kg (10 x 1 kg)

Bending radius 75/100/125/150/175/200/225/250/275/300/325

Clamping device for diameter 5mm and 35mm included

Clamping device for diameter (dimension at buyer`s option)

English

English