Machinery and Production Lines for Cable Production and Cable Manufacture

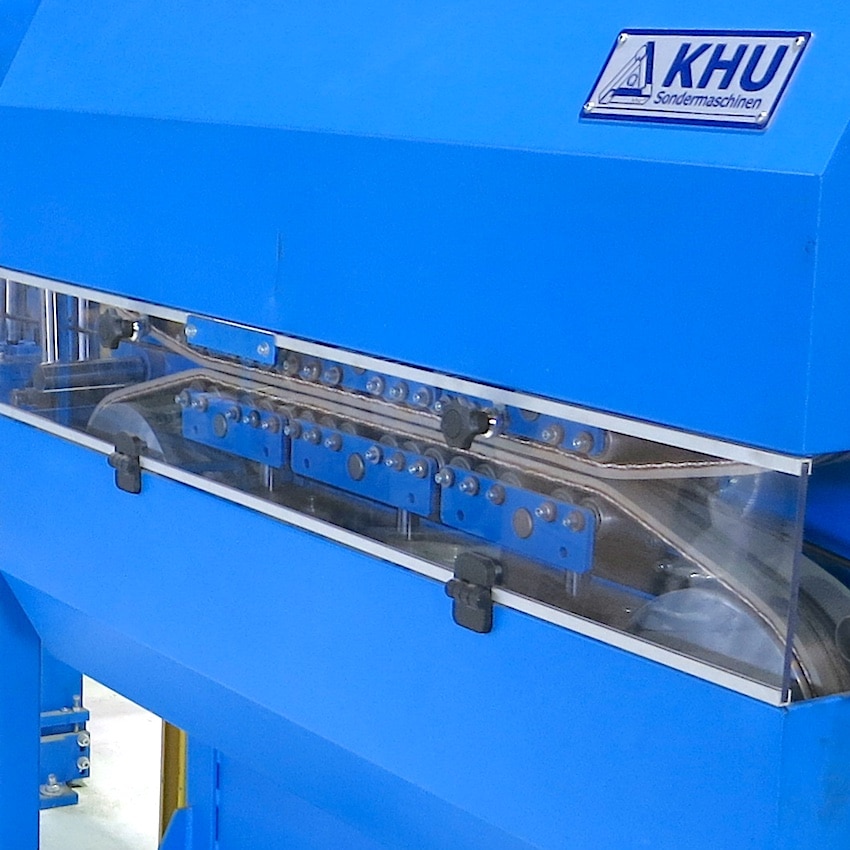

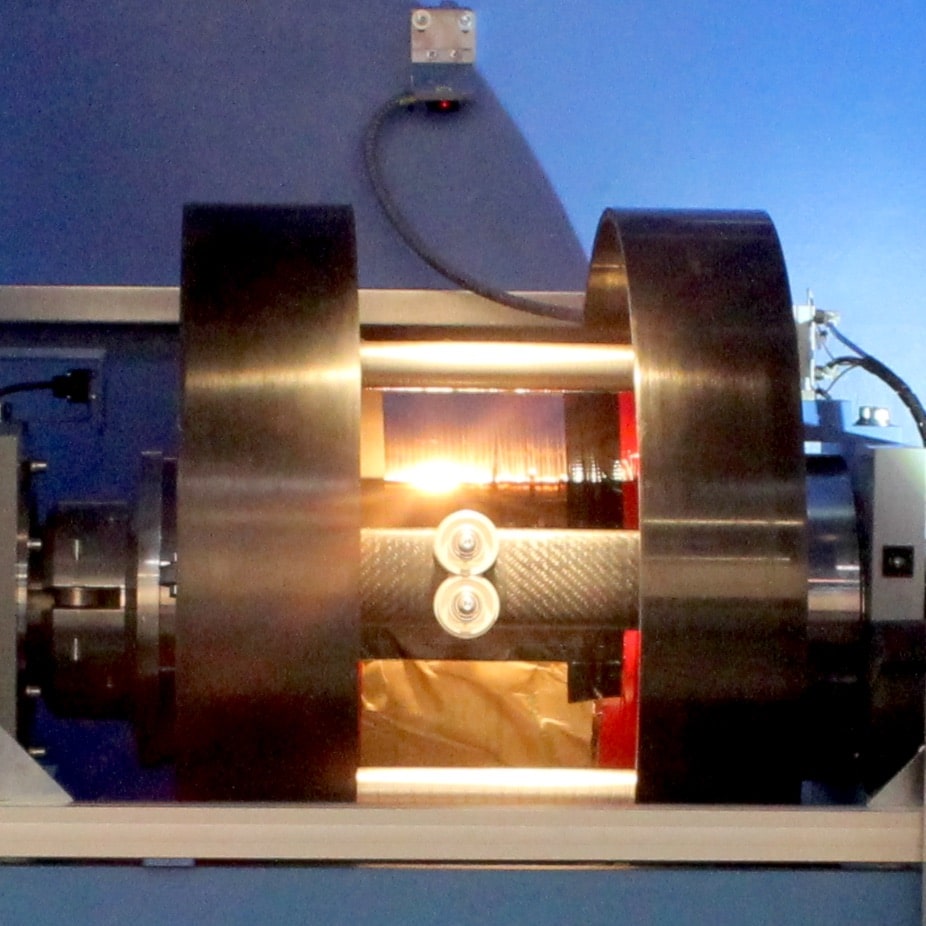

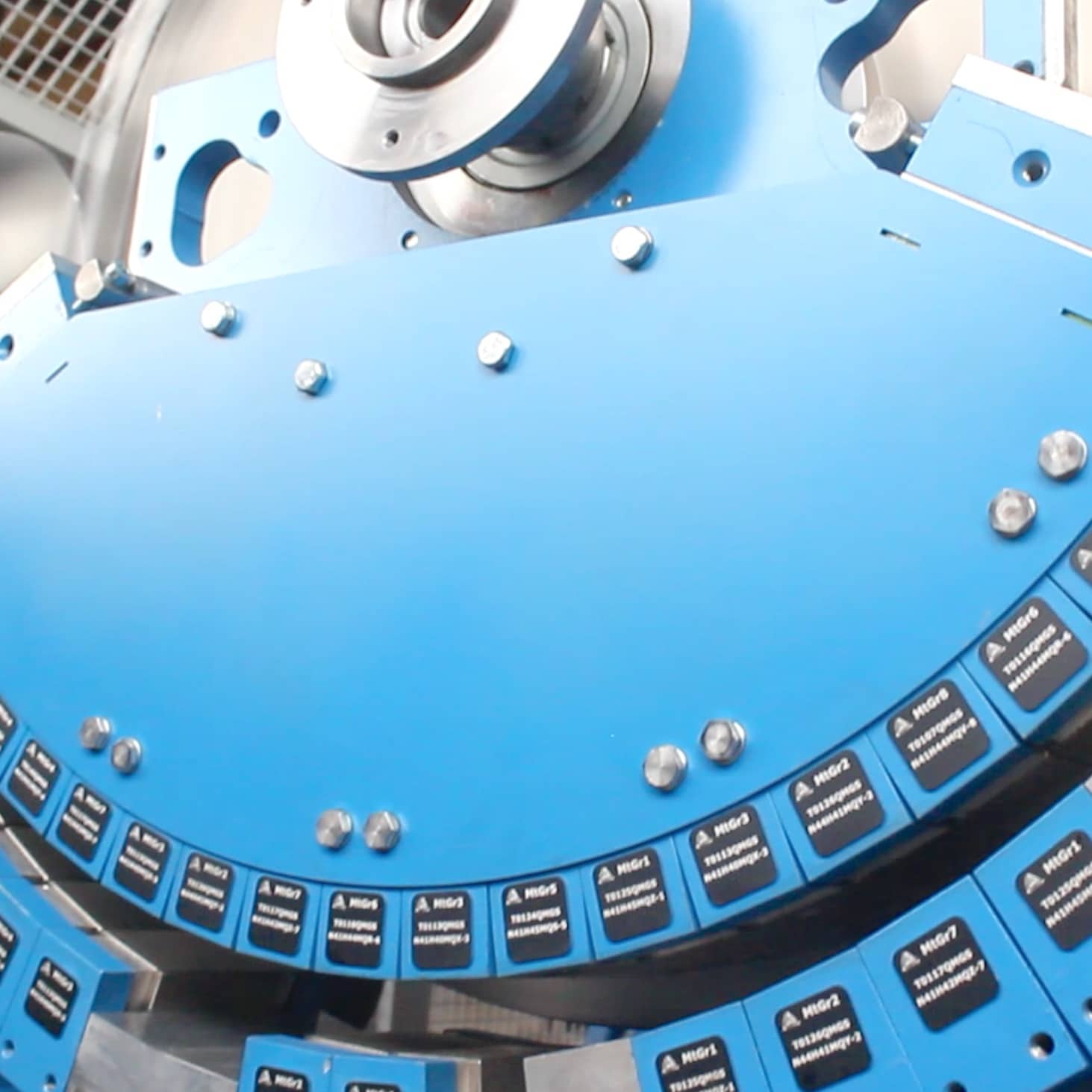

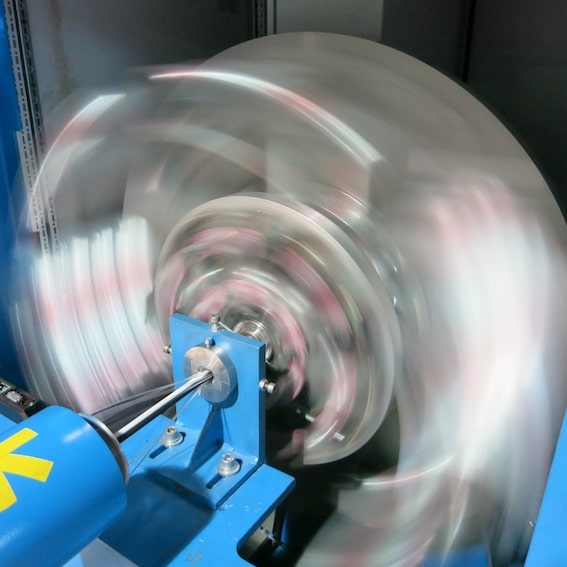

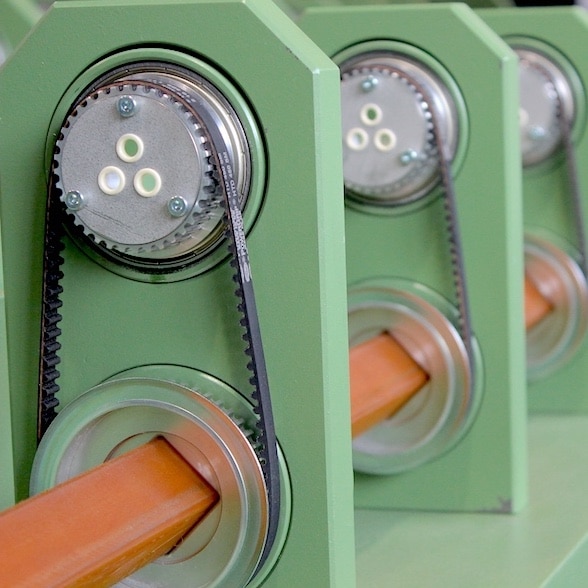

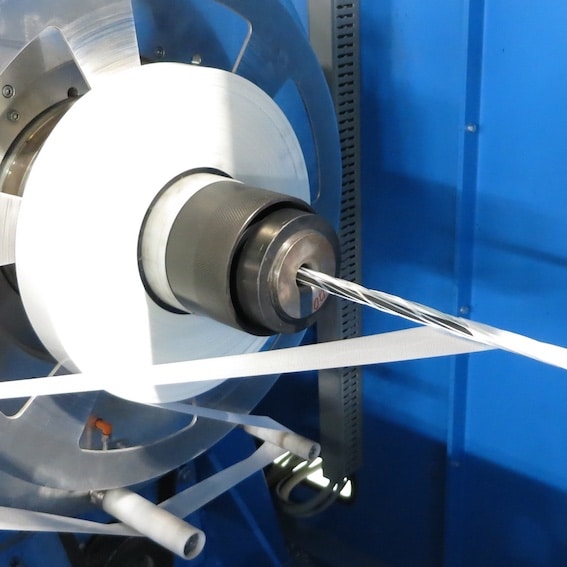

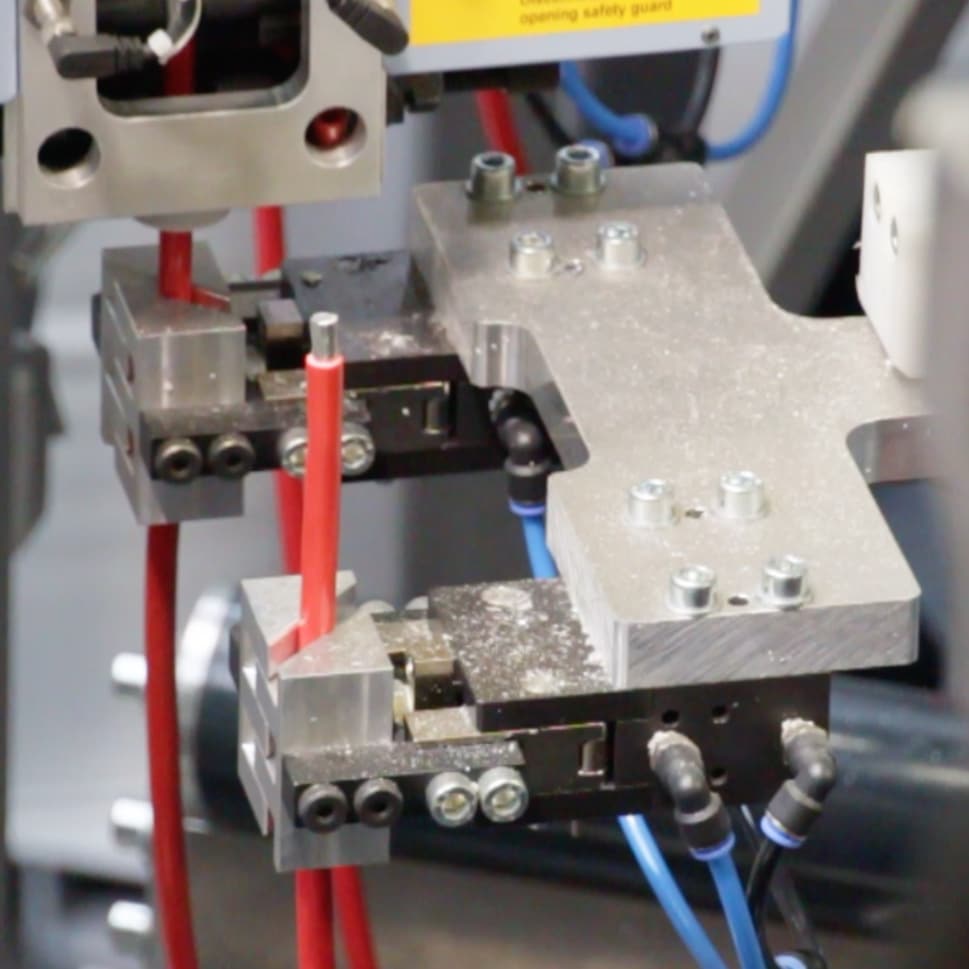

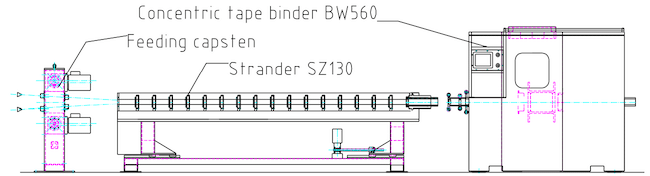

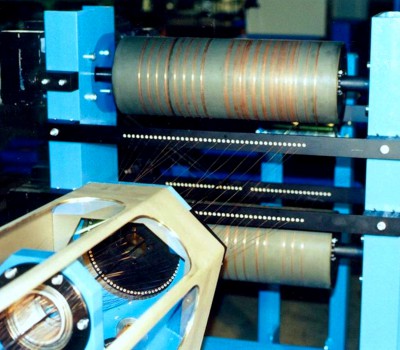

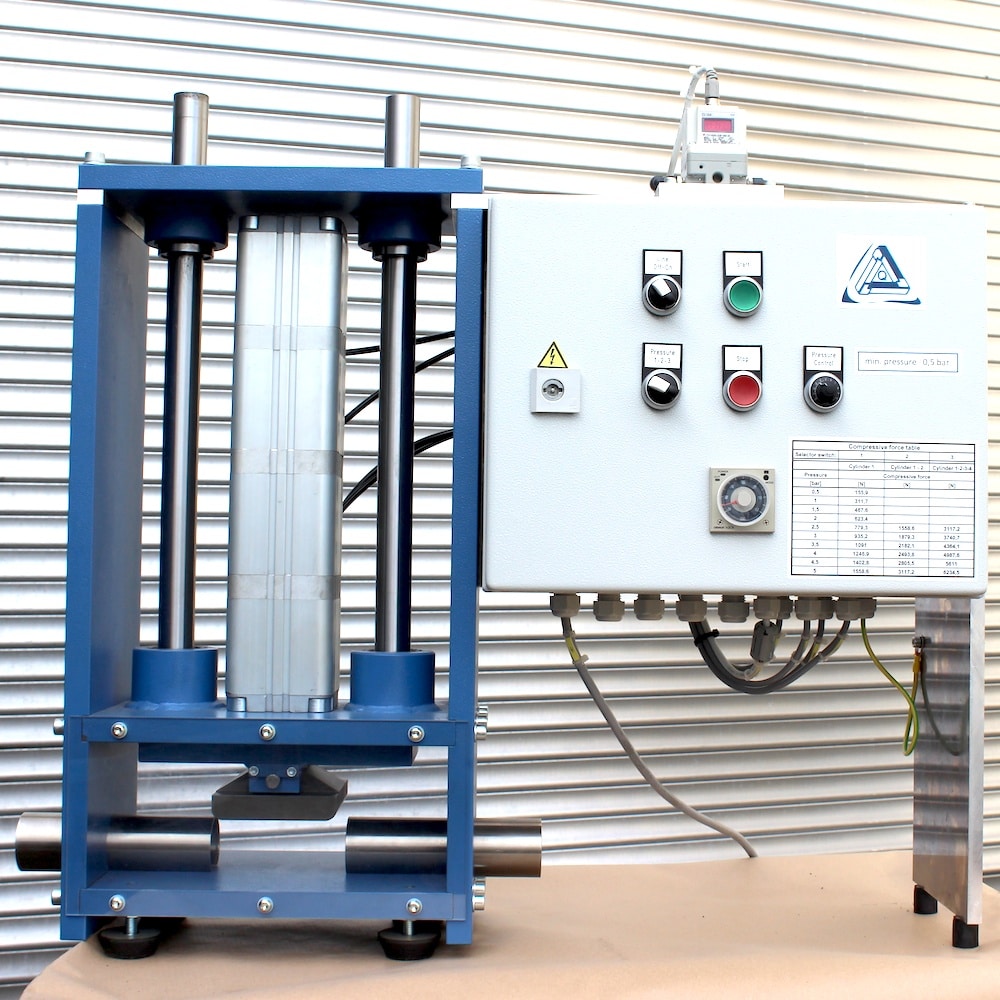

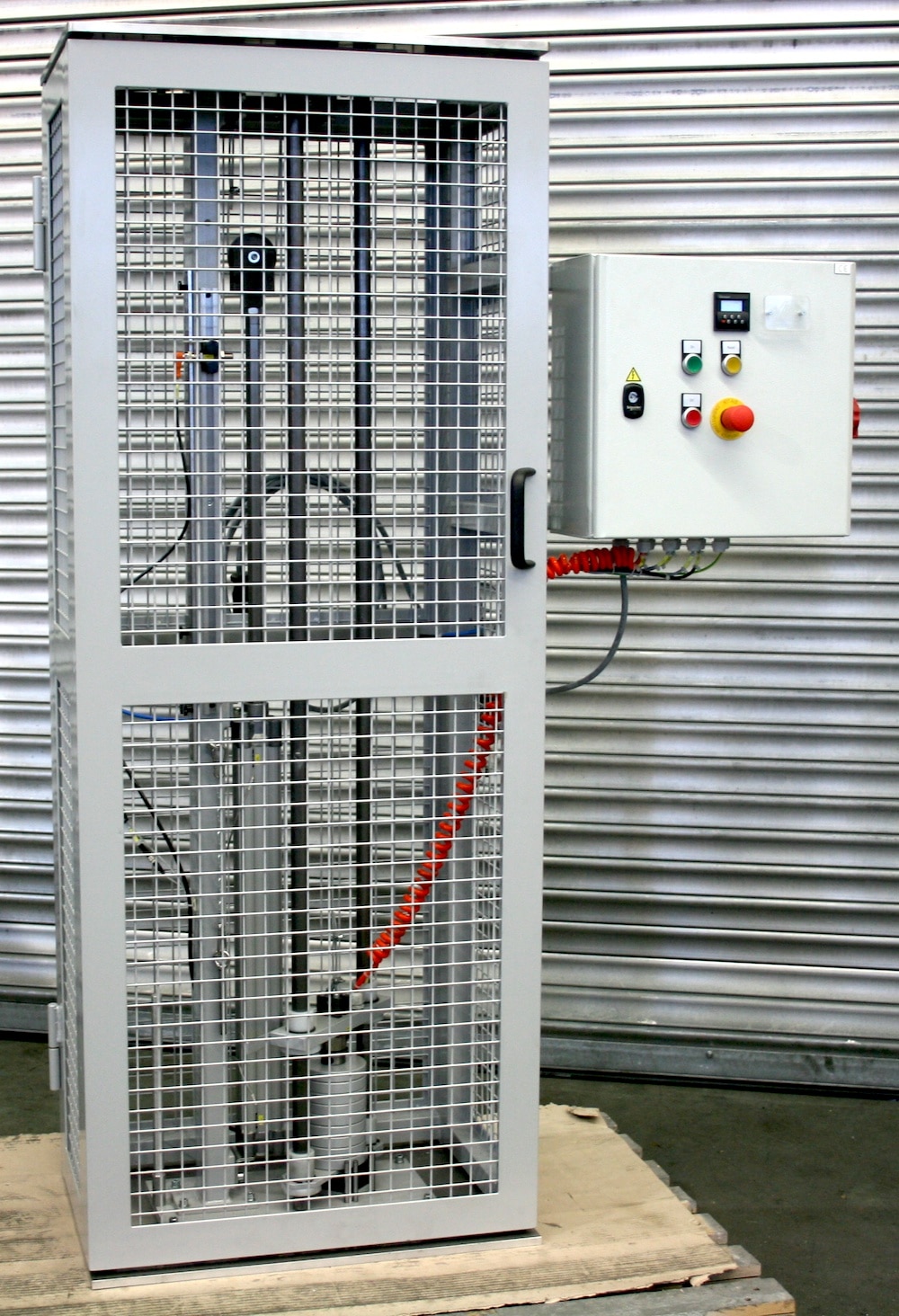

KHU Sondermaschinen develops, designs and fabricates stock and custom machinery and production plants for the cable and wire industry. Our customers value the quality and performance of our cable production plants and automated cable harness plants. Among complete cable production plants we offer a comprehensive supply of components, such as pay-off, take-up, caterpuller and capstans, stranding machinery, twisters and much more. If you can not find what you are searching for please contact us for we are happy to make machinery that does not exist yet. We concentrate on innovative designs to supply our customers with revolutionary products giving them the key competitive advantage.

English

English