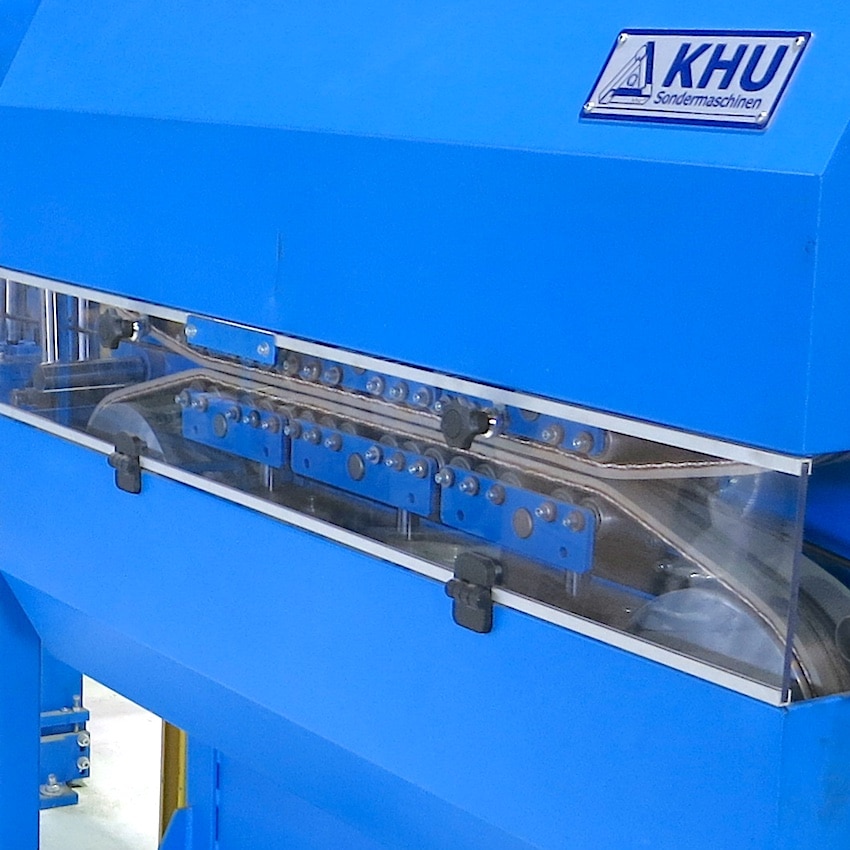

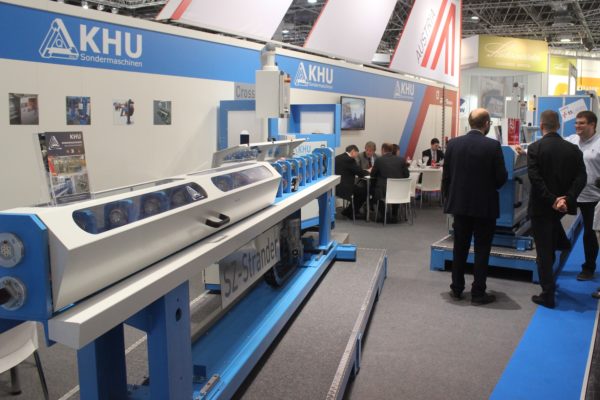

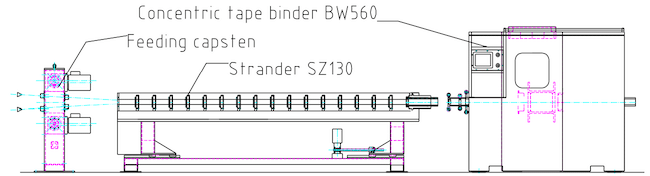

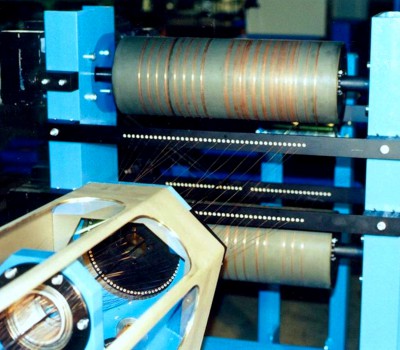

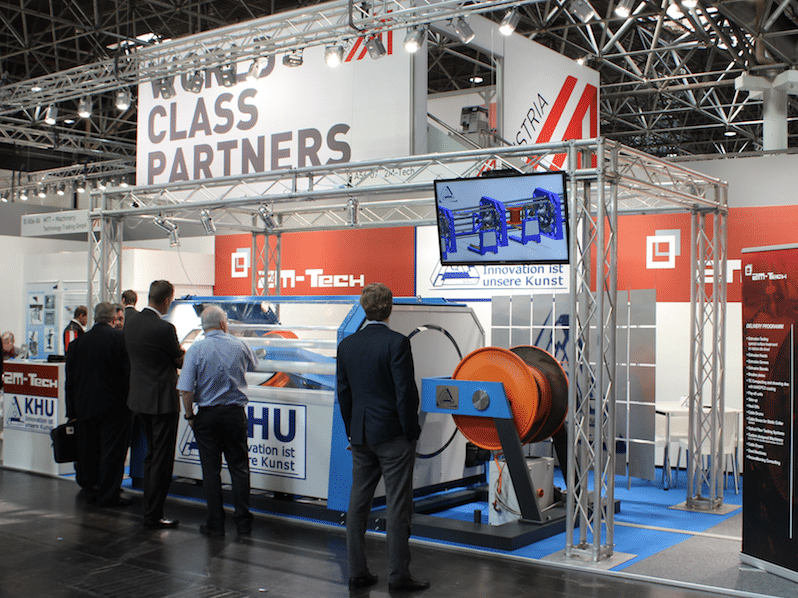

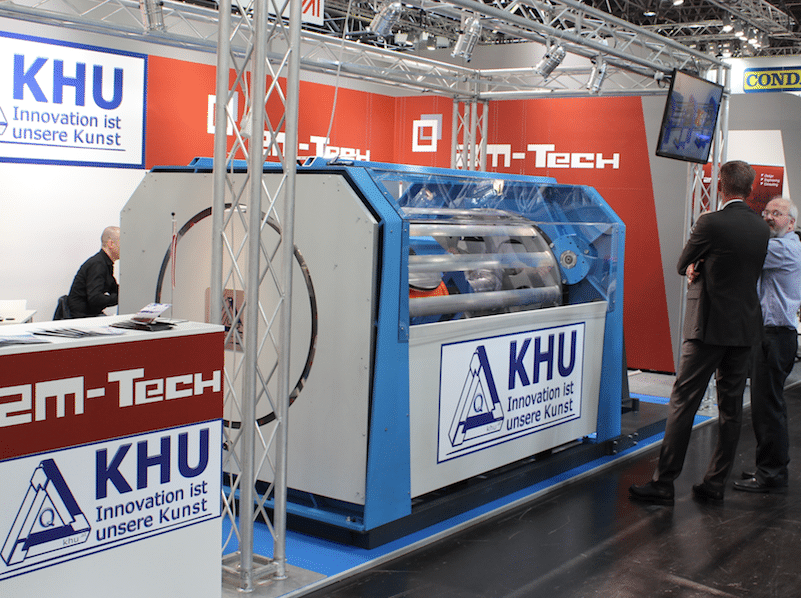

The SZ-40 B is a compact SZ-Strander that enables exact linear stranding over the complete accumulation length of the machine. KHU Sondermaschinen provides suitable SZ-machines as well as complete machine groups for upgrading or adapting your existing production line for the stranding of power cable cores, CU installation cables or for the screening of power cables with Cu-wires.

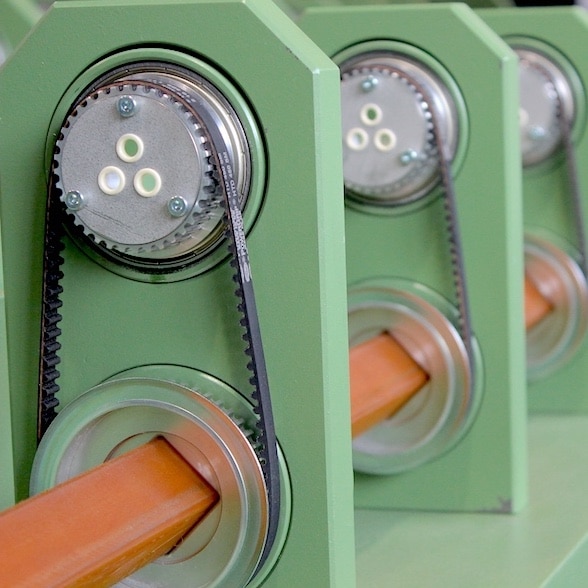

* compact, solid design

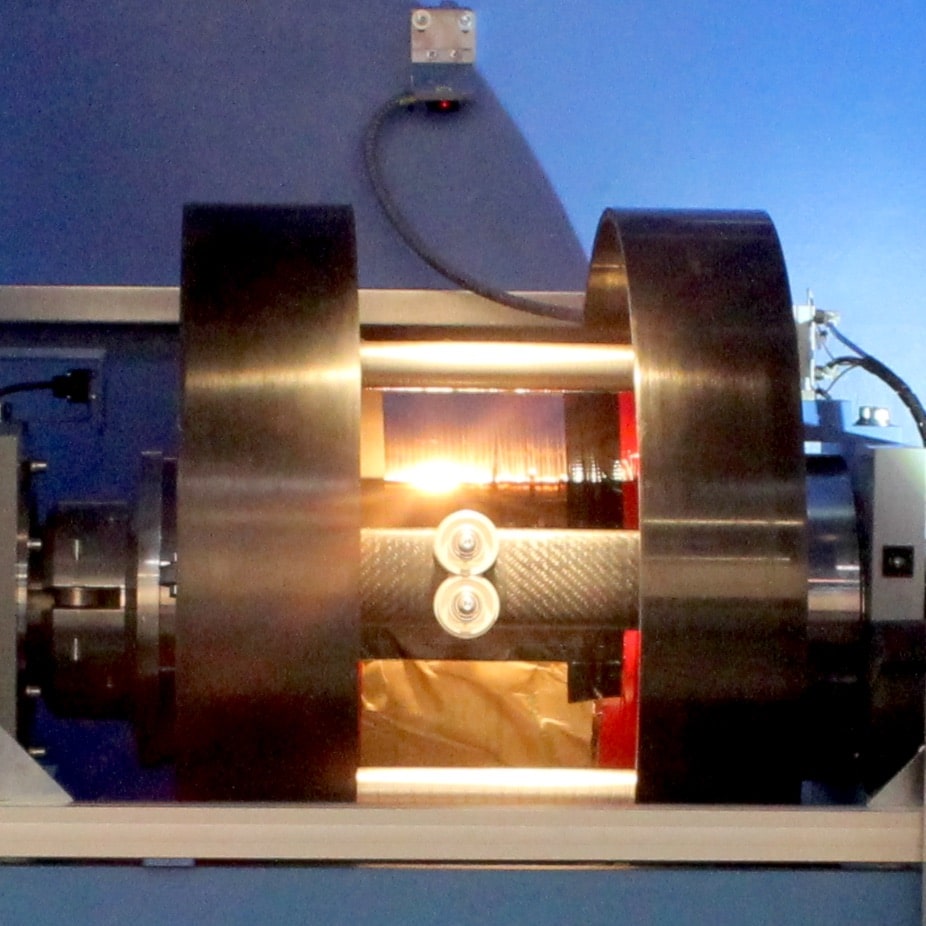

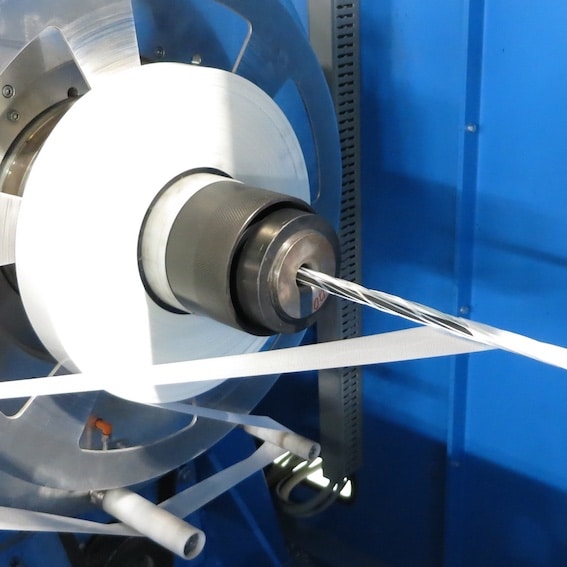

* linear torsion of stranding disk

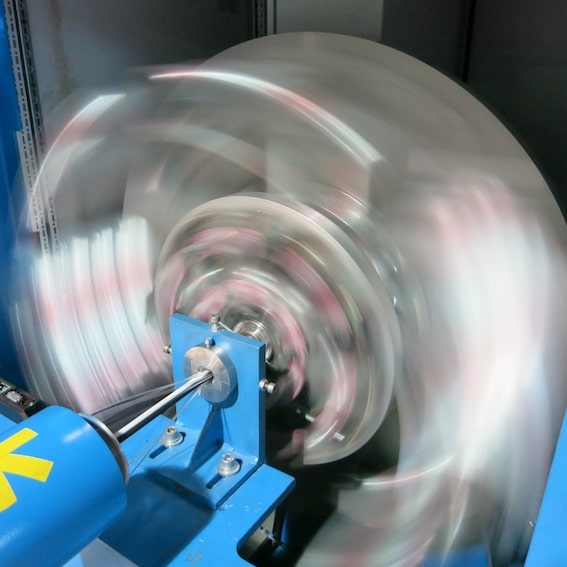

* for high speed production

* high number of twists

* short reversal length

* gentle stranding

* low friction

* direct drive of all elements

* simple to integrate

* including safety devices

* high quality product

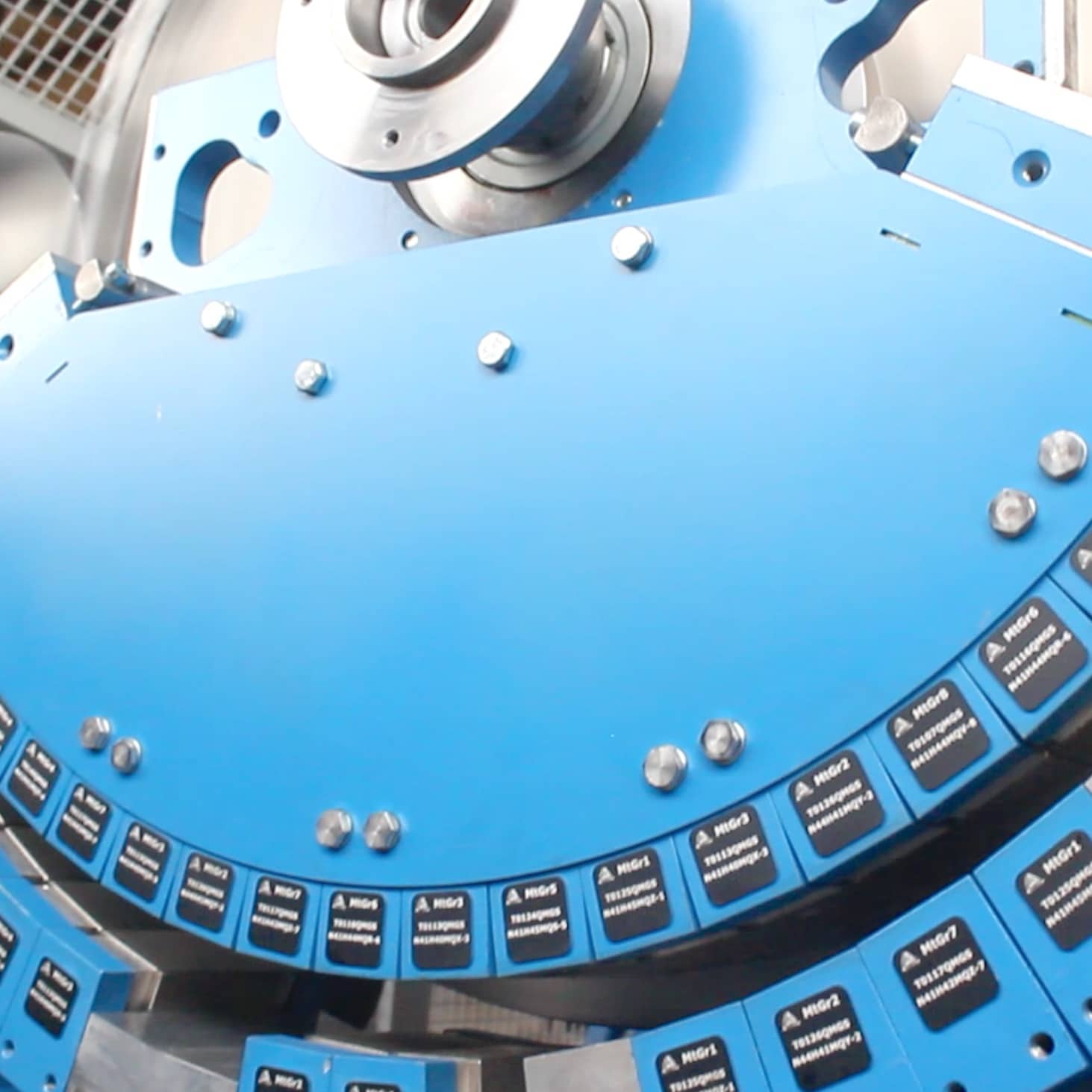

Number of Stranding elements, max … 3-7

Diameter of Stranding elements …… max. 6,0 mm

Typical application …………….. CU-building wire

Accumulator length ……………… 4000 mm

Max. lays per direction …………. max. 12

Max. speed of rotor …………….. 3500 rpm

Max. production speed …………… 500 m/min

Construction length …………….. 4500 – 6000 mm

+ Control system with display

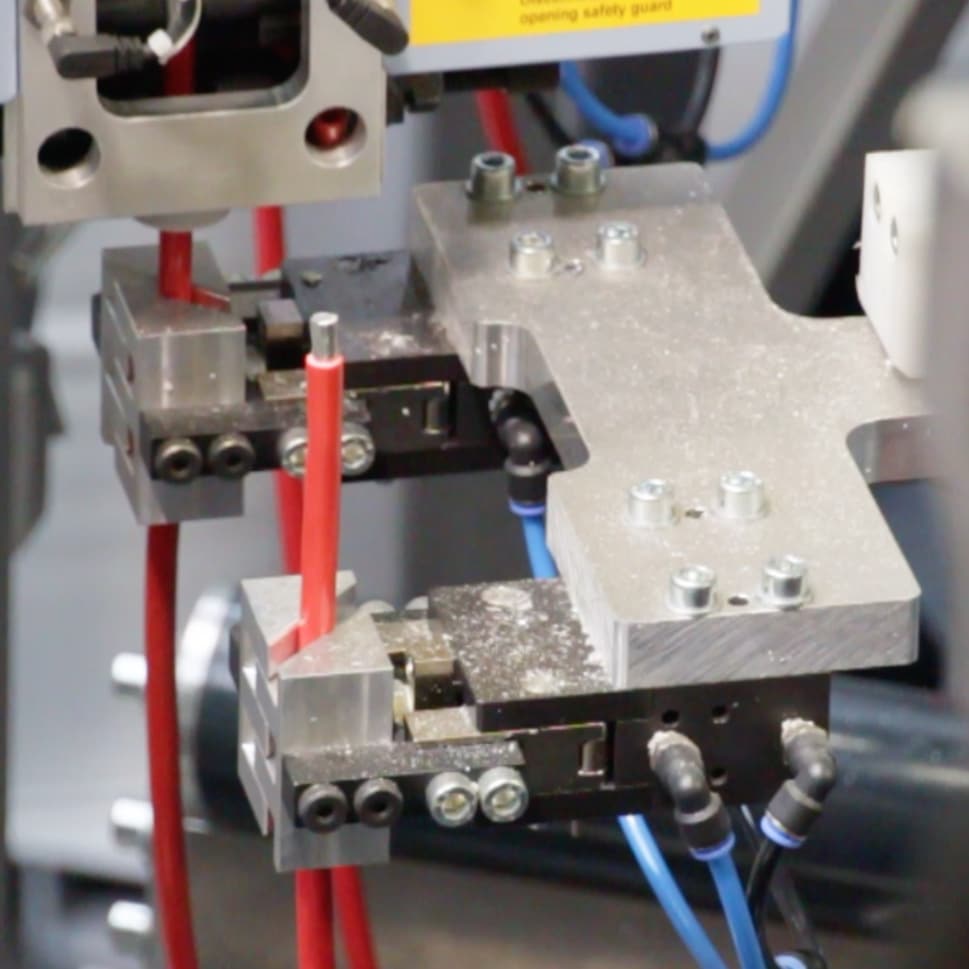

+ Longidutinal movement

+ Cross movement

+ Additional rotor, – stranding disks

+ Tension control unit

+ Paper longidutinal folding for UL-Cables

English

English