Leading companies from many industries rely on the products and services of KHU Sondermaschinen. We have planned, designed, engineered, manufactured, built and started a high number of machines and plants for our customers.

The diversity of our past projects has enriched our experience, making us a competent and innovative partner the most challenging tasks.

Here is a list of a few chosen products.

Boring Machine for Special Screws

Milling and Boring Machine

Worm-Milling Machine

Can Closing Machine

Filter Production Plant

PVC Profile Extrusion

Paper Web turning Equipment

Post- Press Packaging Facility

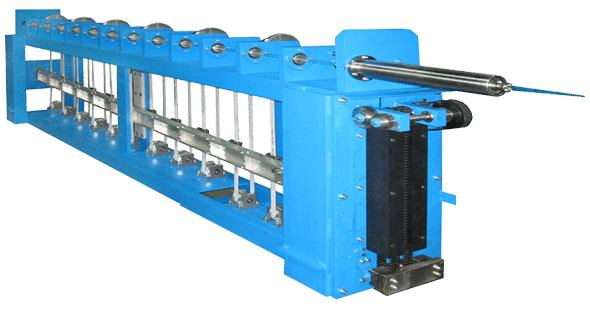

Longitudinal Perforation Machine

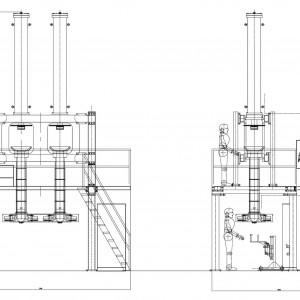

Gas Bottle Filling Plant

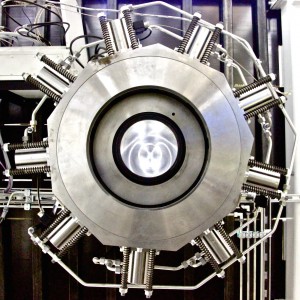

Can Closing Machinery

Bogie Lifting Stand

Welding Facility for Stovepipes

Escalator Stair

Safety Carabines

Q-Drive

Dual Paste Extruder

German

German English

English