According to IEC-794-1-E3-Crush

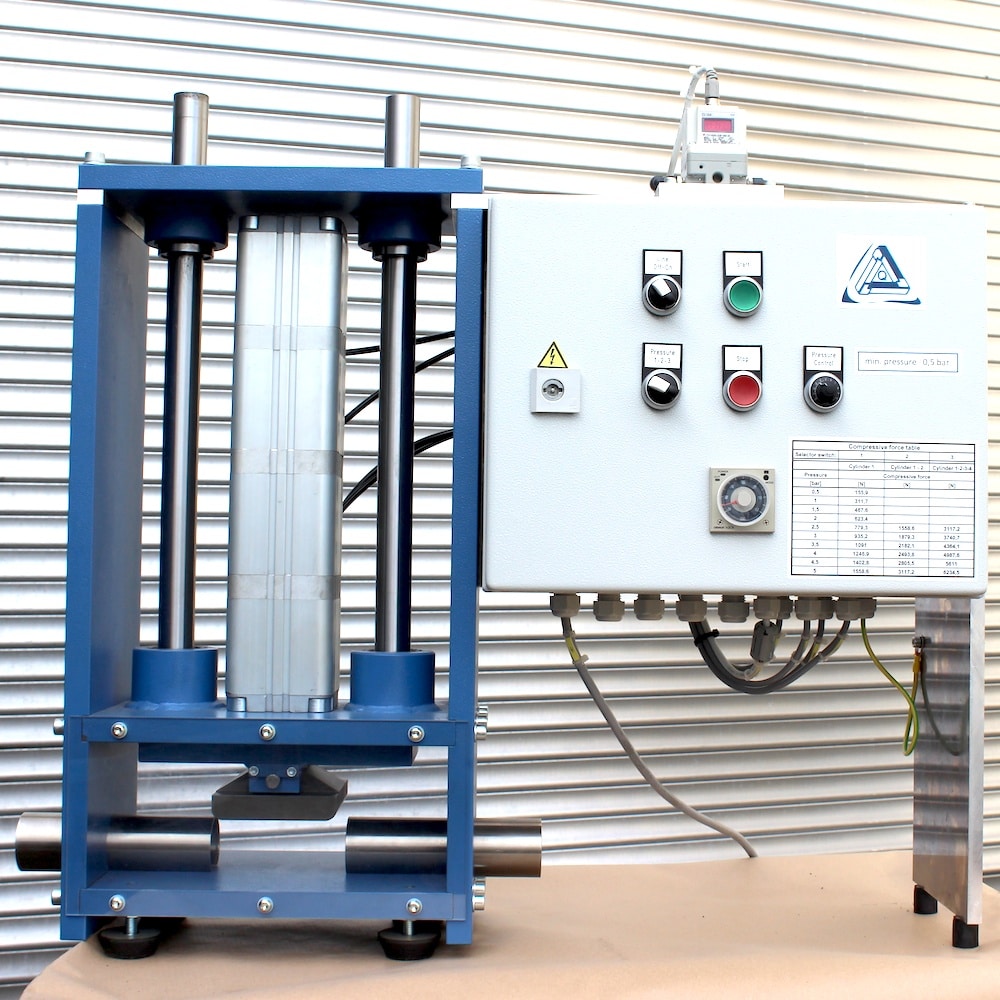

The cable sample is tightened into the testing device, then pinched between a stationary flat steel plate and a movable 100 mm (length) steel plate whereupon transverse pressure is applied on the cable sample.

The desired pressure has to be defined.

An automatic STOP is possible after the expiry of the programmed time.

This test can be executed automatically and manually.

Measuring unit for calibration of pressure setting including display.

Cycle time adjustable 0 – 300 sec

Steel plates 100 x 100 mm

Pressure 20 – 6.000 N

Cable sample length 500 mm

Cable diameter 3 – 40 mm

English

English